Our Products

PARYLENE COATING IS THE MODERN TECHNOLOGY IN CONFORMAL COATING. Parylene is a conformal protective polymer coating material utilized to uniformly protect any component configuration on such diverse substrates as metal, glass, paper, resin, plastic, ceramic, ferrite & silicon. A name that refers to a polymer series based on p-Xylylene POLY(PARA-XYLYLENE). A truly conformal, thin, optically clear, inert coating applied in a vacuum chamber at room temperature. A non-line-of-sight coating that follows molecular level deposition process. A chemically pure coating that does not use any catalysts or leachable materials.

- Optically clear – colourless

- Biocompatible and biostable

- Chemically pure, inert and free of catalytic, plasticizer and solvent residues

- No outgassing

- No leachable ingredients

- No ure forces/stresses

- Environmental friendly

- No thermal stresses during room temperature deposition

- Completely conformal

- Ultra-thin and lightweight

- Free from pinholes and defects

- Moisture & chemical barrier

- High dielectric strength

- Chemical insolubility

- Dry film lubricity

- Particle immobilization

- Hydrophobicity

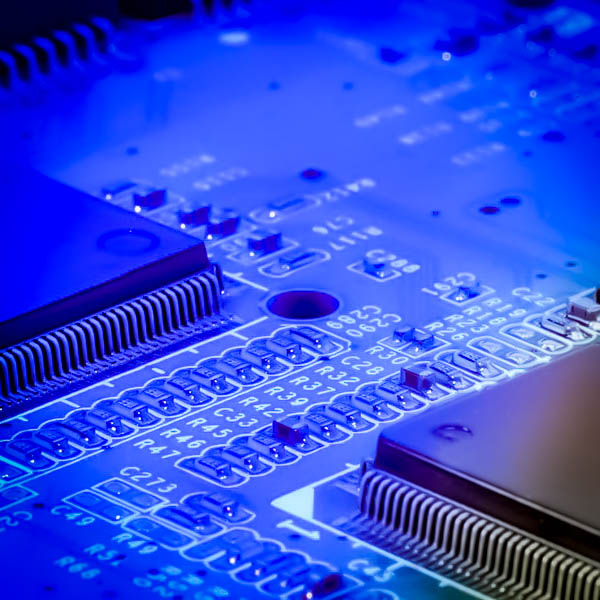

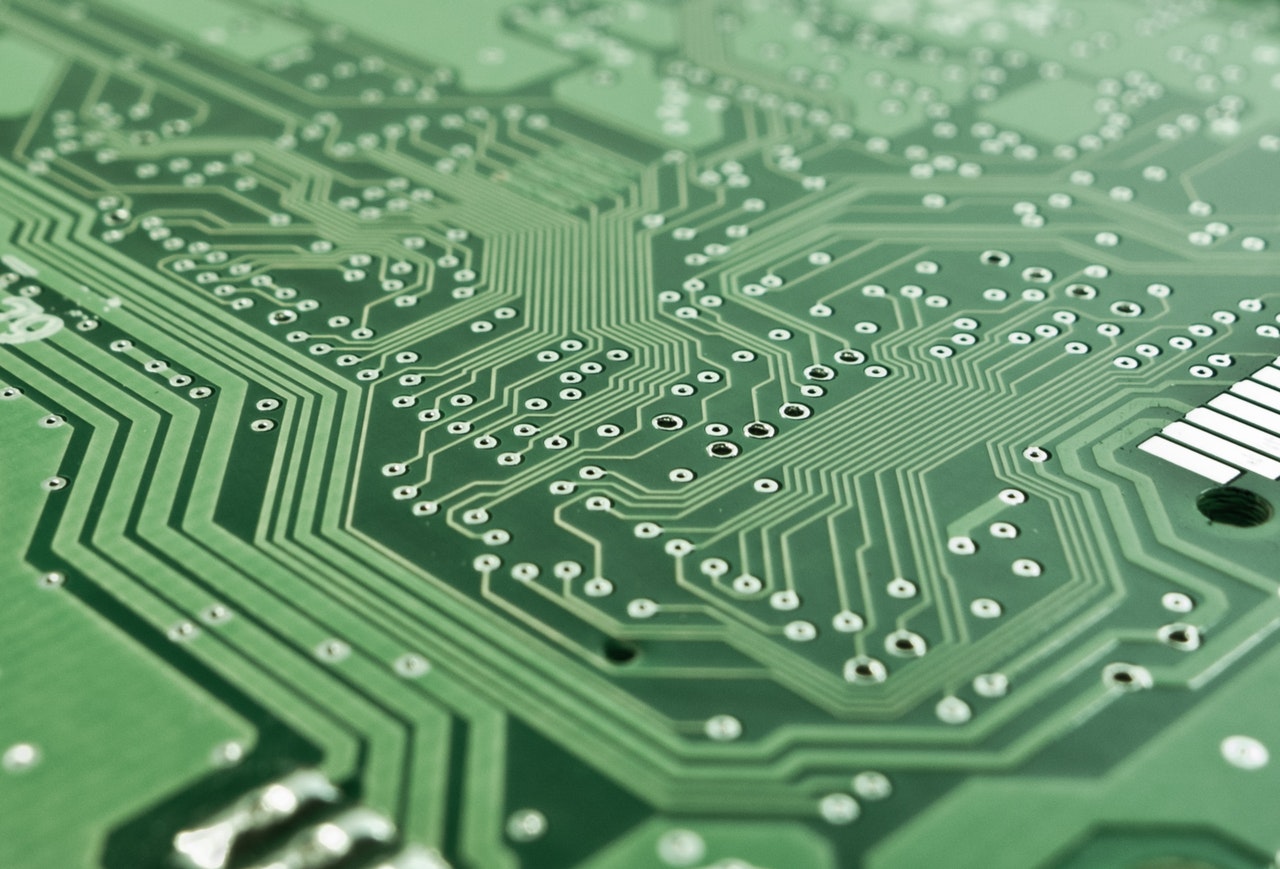

- Parylenes already protect millions of automotive electronics, but they’ll be indispensable for protecting the even more numerous and sophisticated electronics in the EV market of tomorrow.

- With the number of critical electronics in EV systems increasing, ultra-thin, pinhole free Parylene conformal coatings will be essential to delivering the most reliable, high-performance protection for PCBs, ECUs, ADAS, LEDs and more.

- Parylene provides unmatched thermal stability for protection in harsh environments. These coatings, enabling manufacturers to meet regulatory as well as performance milestones as the global industry moves toward an eco-friendly automotive future.

Land Drilling & Fracking

- Dirt

- Dust

- Vibration

- High Pressure

- Moisture/Humidity/weather

- Heat/wide temp swings

- UV Exposure-short or long term

- Dissolve minerals

- Eliminate bacteria

- Prevent clay from swelling or shifting

- Corrosion prevention

- Maintain fluid viscosity

- pH adjustments

- Prevent scale deposits

- Dozens to hundreds that can be used as additives

Offshore Drilling

Corrosion

- Humidity

- Salt fog

Pressure

- Deep sea

- Underground

- Associated with drilling process

Reliability

- More challenging and costly to access

- High cost of down-time

- Redundant Protection needed

- Freedom from by-products

- Application temperatures

- Cure forces

- Conformability -uniformity

- Control of thickness

- Crevice penetration

- Regulation/Biocompatibility

Properties of the coating

- Barrier capabilities

- Environmental stability

- Sterilizability and bio acceptability

- Minimization of mechanical loading

- Printed circuit boards

- MEMS wafers

- Probes/pins

- Rotors/ stators

- Components

- Metal

- Brackets

- Cables

- Ferrite cores

- Video displays

- Electronic billboards

- Marine lighting

- Transportation signage

- Outdoor illumination

- Vehicle lighting

- Commercial refrigeration

- Aviation lighting

- ICDs, pacemakers, VADs

- Drug delivery devices

- Stents, inhalers(MDI, DPI, nasal)

- Cochlear and intraocular implants

- Catheters

- Neurostimulators

- Gastric balloons and cuffs

- Endotracheal tubes

- Laboratory devices

- Printed circuit boards

- Printed circuit boards

- Semiconductor wafers

- Military PBCA

- Consumer Electronics

- Automotive Electronics

- Microelectronic Mechanical Systems (MEMS)

- Medical PCBA